This photo shows the front face of the barn after the slates were removed, before the battens were stripped. You can see the mortar packing clearly.

Before we stripped the battens, we were advised by a neighbour to use a piece of wood (a new batten is ideal) to make a batten gauge.

This involved laying a new batten at right angles to the roof while the old battens were still in place and marking off the tops of the existing battens (and noting which it is!) on this gauge.

We also noted which was the top and bottom of the gauge. Our battens were parallel to the roof but I suppose if the battens vary across the roof, you would repeat with different gauges and note their position along the roof.

This was invaluable for us as we were able to know where to relocate the new battens in order to anchor the old slates.

Accuracy is all we have come to discover - a half inch is crucial when replacing slates.

We replaced the old timber with new, tanalised (sp?) or treated, rough cut timber. No trusses here - we needed the roof space and were trying where possible to be sympathetic.

The old rafters were 2" x 3" (replaced with 2" x 4") at the same spacing as the old rafters. This was dictated by use of the grooves in the original stonework, even though it meant closer spacing (ca. 2' centres) than specified by the architect (ca. 3.5').

The battens (old and new) were 1" x 2". The wall plates were lengths of 3" x 4". The ridge plate was 6" x 1" and contrary to instincts, is non-load bearing. I will explain the structure in another post, but the ridge plate does not carry any load in this roof design.

A mistake we made (a mixture of naivety and dumb luck) was cutting the rafters before the wall plates. This was an honest mistake as we were blindly replicating the old rafters. It meant the rafters were too short to overhang at the eaves line (the original roof had no overhang). As a result we had the additional hassle of cutting dummy rafters, secured to the wall plates and rafter ends which stuck out to kick up the eaves course of slates and carry fascia and guttering. This photo was taken before the wall plates were installed.

This ought to be balanced with a decision we made which was correct (albeit a mixture of luck and judgment)...

If you want to preserve the original roof profile, the chances are it is dictated NOT by the ridge plate but by the purlins which the rafters rest on. We elected to preserve the old purlins. As these supported the rafters and had sagged over time, so too the new rafters echoed this sag along the roof line. Although the new ridge plate was the first piece of new timber we put up, it only rested in place and gave a useful brace and reference point. After the rafters were in place (yes, and the wall plates!) we cut the new ridge plate to follow the profile of the rafter tops - relatively trivial step on our small roof.

If you want to preserve the original roof profile, the chances are it is dictated NOT by the ridge plate but by the purlins which the rafters rest on. We elected to preserve the old purlins. As these supported the rafters and had sagged over time, so too the new rafters echoed this sag along the roof line. Although the new ridge plate was the first piece of new timber we put up, it only rested in place and gave a useful brace and reference point. After the rafters were in place (yes, and the wall plates!) we cut the new ridge plate to follow the profile of the rafter tops - relatively trivial step on our small roof.

This photo was taken before the ridge plate was cut and shows how the rafter heads follow the line of the old sagging purlins (hidden) that they rest on.

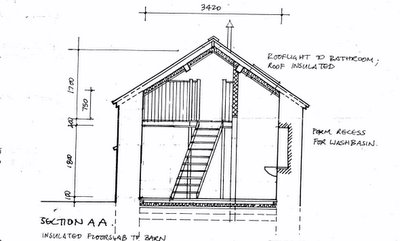

The interior, like the exterior will respect the traditional construction, with slate and wood flooring. Section AA shows the crog loft above the living area, with the shower room and recessed hand basin on the RHS.

The interior, like the exterior will respect the traditional construction, with slate and wood flooring. Section AA shows the crog loft above the living area, with the shower room and recessed hand basin on the RHS.